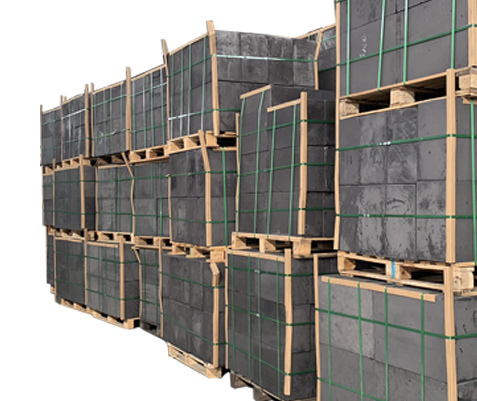

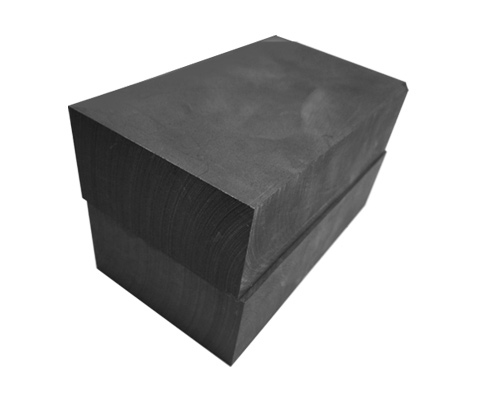

The graphite block is solid and is usually composed of synthetic graphite, such as graphite molds. Small graphite blocks constructed of flake graphite, such as carbon brushes, are also available. Graphite is usually in the form of powders, such as flake graphite and earthy graphite powder. Graphite's form properties include being soft and dark grey, having a greasy texture, and the ability to infect paper. It has a hardness of 1-2, which can increase to 3-5 in the vertical direction as impurities increase. It has a specific gravity ranging from 1.9 to 2.3. It is one of the most temperature-resistant minerals with a specific surface area range of 1-20m2/g in the absence of oxygen and a melting point of 3000 °C or more. It has the ability to conduct both electricity and heat. The role of graphite plate in the smelting industry: Graphite can be used to manufacture graphite crucibles, protective agents for steel ingots, and magnesia carbon bricks for smelting furnace linings in the smelting industry. Because of its superior thermal conductivity and anti-corrosion properties, graphite is widely utilized in the chemical, electronic, steel, and pharmaceutical sectors. Graphite is a crystalline material that offers exceptional lubricity, chemical stability, high-temperature resistance, electrical conductivity, unique thermal conductivity and plasticity, coating, and other properties. It has a wide range of applications. Let WH graphite block supplier share with you.

Ⅰ. The application of graphite blocks in metallurgy

Graphite blocks for sale are used in powder metallurgy, primarily in the sintering process, as an industrial graphite product arising from further processing of graphite electrodes. The raw material is placed on the graphite block and melted at high temperatures in a sintering furnace or vacuum furnace. The graphite block can match the requirements of the powder metallurgy industry due to its high temperature and oxidation resistance, and it can be used again, saving the client money!

Ⅱ. The application of graphite blocks in the foundry industry

Another example is the use of graphite blocks in the foundry sector. In a pure graphite crucible, the metal can be heated to 1500℃ to turn it into a liquid, which can then be cast into the desired industrial product using the graphite casting method. In a nutshell, graphite casting is identical to metal casting. The features of graphite: It is used for casting copper and aluminum alloys. Thermal conductivity and thermochemical stability are both excellent. Casting tin bronze and aluminum-iron bronze with graphite can help to eliminate casting flaws including shrinkage, loosening, and pinholes while also improving mechanical performance.

English

English