Graphite, as a non-metallic resource mineral, has been widely used in the aerospace field, such as sealing material and throat lining material, because of its self-lubricating performance, easy molding, good thermal conductivity, thermal stability, and chemical stability. Lets look more about molded graphite block, and other graphite products for aerospace industry.

Characteristics of High-Temperature Graphite in Aerospace Industry

High-temperature graphite material has the characteristics of high-temperature resistance, ablative resistance, and lightweight, so it can be used as the throat lining material of SRM for small rockets. In the early 1960s, the siliconized KS-8 high-strength graphite material jointly developed by the Metal Research Institute of the Chinese Academy of Sciences, Xi 'an Aerospace Composite Materials Research Institute, and Jilin Carbon Factory can be used as the first generation of throat lining material. The KS-8 graphite throat lining material has been successfully applied to the final SRM of Dongfanghong No. 1.

Development of High-Temperature Graphite in Aerospace Industry

Isotropic graphite materials originated in the 1960s. Compared with other graphite materials, isotropic high-temperature graphite materials have better comprehensive performance, and the molding process is also different. The cold isostatic press is generally used as equipment, and petroleum coke and asphalt coke are treated as raw materials after special treatment. The isotropic high-temperature graphite material prepared has the characteristics of high compressive strength and bending strength, uniform and dense structure, high density, high precision and finish of the sealing surface after processing, and low opening rate, so it is also called high-density and high strength graphite material.

In Russia, isotropic pyrolytic graphite material is used as sealing material in turbopumps of the new generation of high thrust space engines. The sealing performance of the sealing ring is good, and there has been no leakage accident at present.

Graphite Products for Aerospace Industry

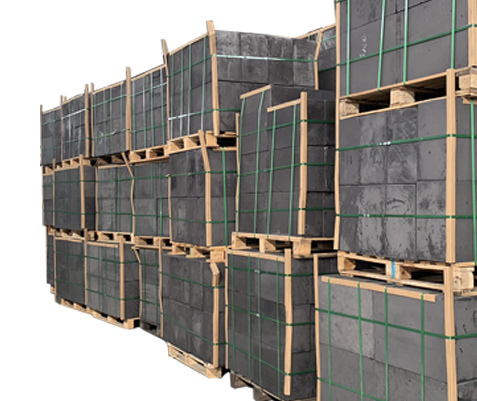

WH Graphite has established itself as a trusted supplier of high-quality graphite products for the aerospace industry, offering exceptional precision and performance. Their Isostatic Graphite Block and Isostatic Graphite Rods are integral components for various aerospace applications.

Isostatic Graphite Blocks are renowned for their uniform material structure, high density, and isotropy, making them ideal for crafting intricate components like rocket nozzles, rudders, and electrical discharge machining electrodes. The superior thermal stability and resistance to extreme temperatures ensure these blocks meet the exacting demands of the aerospace sector.

Isostatic Graphite Rods, with their remarkable properties of high-temperature resistance and isotropy, are essential for manufacturing aerospace components that require precision and reliability, such as satellite structures, rocket igniters, and more.

WH Graphite's commitment to excellence and cutting-edge technology ensures that their graphite products meet the stringent standards of the aerospace industry, making them an indispensable partner for producing high-performance, mission-critical aerospace components.

English

English