At high temperatures (the sintering temperature of most copper matrix is above 800℃), the strength of the graphite mould will increase with temperature increase.

Graphite has gradually become the preferred material for die and mould production with its good physical and chemical properties. China also attaches great importance to the development of carbon graphite molds. The level of die and graphite mould production technology has become an important symbol to measure the level of a country's product manufacturing because the die largely determines the quality of products, benefits, and the development ability of new products. Carbon graphite molds with their superior performance in all aspects have established an important leading position in the mold industry and the future development trend. WH graphite, a big graphite mould supplier, provides custom graphite molds according to customers' requests.

Carbon graphite molds are used for color metal continuous casting and semi-continuous casting; non-ferrous metal pressure casting; centrifugal casting.

You can also find the applications of graphite molds for sale in hot pressing film, glass forming, sintering and other carving graphite molds.

At high temperatures (the sintering temperature of most copper matrix is above 800℃), the strength of the graphite mould will increase with temperature increase.

Carbon graphite molds have excellent thermal and electrical conductivity.

Low linear expansion coefficient, the graphite molds for sale have good thermal stability and resistance to heating impact.

Chemical corrosion resistance and most metals are not easy to react.

WH graphite molds have good lubrication and wear resistance for different applications.

By tooling design personnel according to the requirements of the product components used, the die structure design, drawing drawings again by skilled workers, according to the drawings requirements through all kinds of mechanical processing.

For Example, lathe, planer, milling machine, grinding machine, edm, wire cutting and other equipment) to do the mold of each parts, assembly and debugging, until to produce qualified graphite mould products.

WH graphite is a manufacturer of graphite raw materials. The raw materials of our graphite molds for sale are processed from petroleum coke and asphalt coke. With advanced equipment, exquisite technology, and stable quality, we are in the leading position in the carbon graphite molds industry. The advantages of raw materials provide favorable conditions for the processing of graphite molds.

Unlike other graphite mould manufacturers, we have our own graphite production line and R & D team to meet the needs of customers. We can recommend suitable graphite mould types and specifications according to your requirements. We can also provide impregnation, baking, coating, and graphitization services to meet the different needs of customers.

WH graphite molds have passed the ISO9001:2015 quality management system certification. We strictly follow the standard operating procedures of making a graphite mold so as to ensure the consistency and stability of the graphite molds for sale.

The factors affecting the graphite molds are as follows:

1. Environment: in the air, the oxidation speed will be accelerated with the increase of temperature, thus shortening the service life of carbon graphite molds; In a vacuum, the oxidation speed will be slow and the life can be prolonged.

2. Material selection: because the graphite mould has different functions in the thermal field, the materials used for the graphite molds for sale must be different. In general, the electrode, heater, graphite crucible, insulation cylinder, etc. should be processed with graphite materials with fine structure and high strength produced by isostatic pressing to meet the actual needs of production.

Graphite ingot molds receive liquid metals of precious metals and other types of metals and preserve them until they solidify, which are later used for investment or storage for jewelry use.

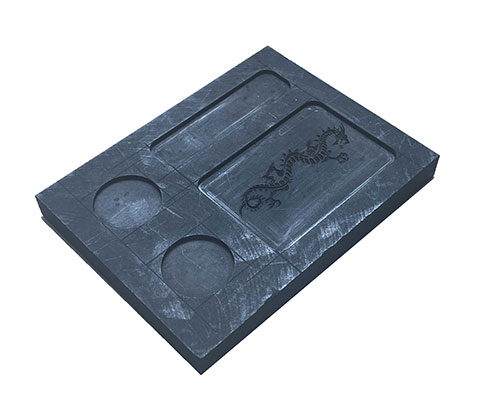

Our custom graphite ingot molds are made of high-density fine-grained graphite, with various sizes and shapes of square, rectangular and cylindrical. The smooth cavity finish of the graphite gold ingot mold makes the ingot very easy to take out without sticking to the mold itself. Graphite copper ingot mold is more suitable for refining than silicon carbide graphite crucible, with excellent thermal stability and suitable for rapid heating and cooling.