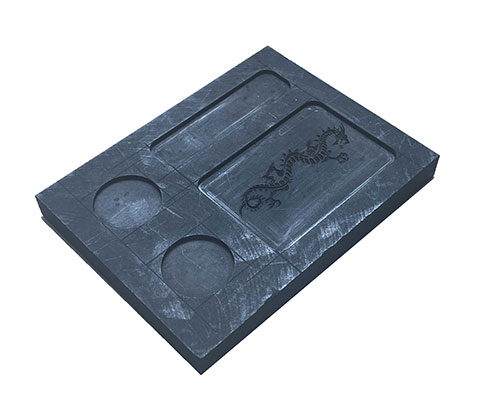

What's the difference between graphite ring molds and metal ring molds?

Graphite ring molds, while less costly and more resistant to warping under high temperatures compared to metal counterparts, may impart a slightly rougher finish to the glass ring. This difference in finish arises from the inherent properties of the materials; graphite tends to have a slightly coarser texture than metal. However, graphite molds excel in thermal stability and are often preferred for their durability and longevity in glassmaking processes. Conversely, metal ring molds, such as silver casting molds, offer a smoother finish but come with a higher price tag and susceptibility to deformation under extreme heat. Glass artisans weigh these factors when selecting between graphite and metal ring molds, balancing cost, durability, and desired surface finish in their creative endeavors.

How do graphite ring molds compare to other types of molds, such as ceramic or metal, in terms of longevity and durability?

Graphite ring molds offer distinct advantages and considerations compared to ceramic or metal molds in terms of longevity and durability:

Longevity:

Graphite ring molds are renowned for their exceptional longevity. They boast a high resistance to thermal shock and degradation, making them capable of enduring prolonged exposure to high temperatures without significant deterioration.

Ceramic molds, while durable, may be more susceptible to cracking or chipping over time, especially if subjected to rapid temperature changes or mechanical stress.

Metal molds vary in longevity depending on the type of metal used. Some metals may corrode or degrade over time due to chemical reactions with molten glass, impacting the mold's lifespan.

Durability:

Graphite ring molds are highly durable, capable of withstanding repeated use in glassmaking processes without significant wear or deformation. They maintain their structural integrity even after extended exposure to heat.

Ceramic molds are generally durable but may be prone to breakage or damage if mishandled or subjected to sudden temperature changes.

Metal molds can be durable but may deform or warp under high temperatures, especially if made from less heat-resistant metals. Additionally, some metals may react with molten glass, affecting the mold's longevity and performance.

Graphite ring molds excel in both longevity and durability due to their resistance to thermal shock and degradation. While ceramic and metal molds also have their merits, graphite molds are often favored for their reliability and ability to withstand the rigors of glassmaking processes over extended periods.

English

English