Silver jewelry holds a timeless allure, captivating wearers with its lustrous elegance. Behind every exquisite piece lies a meticulous manufacturing process, with silver casting molds playing a pivotal role in bringing these designs to life. From inception to mass production, the journey of crafting silver jewelry molds entails a series of intricate steps and careful considerations. In this article, we delve into the nuances of silver casting molds manufacturing, exploring each stage in detail.

Silver Casting Molds Design: Precision in Form and Function

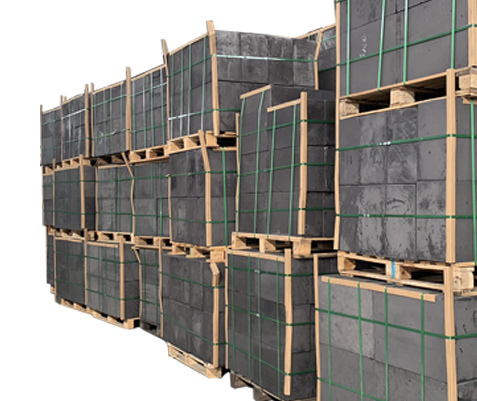

The journey of crafting graphite mold for silver, commences with meticulous design. Each mold's shape and dimensions are meticulously tailored to reflect the intricacies of the intended jewelry piece. Factors such as the size, material, and desired processing techniques of the jewelry influence the mold design process significantly. Designers must strike a delicate balance between aesthetic appeal and practicality, ensuring that the resulting molds align seamlessly with the envisioned jewelry designs.

Silver Casting Molds Material Selection: Choosing the Building Blocks

Selecting the appropriate mold material is a crucial decision that shapes the entire manufacturing process. Common options include RTV silicone rubber, polyurethane rubber, and epoxy resin, each offering distinct advantages suited to varying applications. Factors such as the complexity of the jewelry design, desired level of detail, and cost considerations play pivotal roles in determining the most suitable material for the molds.

Silver Casting Molds Making: Transforming Vision into Reality

With the design finalized and materials selected, the mold-making process commences. Depending on the chosen material, craftsmen employ specialized techniques to fabricate molds with precision and accuracy. From RTV silicone rubber to polyurethane rubber and epoxy resin, each material necessitates specific procedures to ensure optimal results. Meticulous attention is paid to detail during the pouring, vacuumizing, and curing stages, culminating in the creation of molds ready to bring jewelry designs to fruition.

Prepare RTV silicone rubber and curing agent in the prescribed ratio.

Mix the components thoroughly to achieve a homogeneous blend.

Pour the mixture into the mold box and eliminate air bubbles through vacuumization.

Allow the silicone rubber to cure at room temperature for 24 hours, ensuring optimal strength and resilience.

Prepare polyurethane rubber and curing agent as per the recommended ratio.

Thoroughly blend the components to ensure uniform consistency.

Pour the mixture into the mold box and evacuate any entrapped air.

Allow the polyurethane rubber to cure at room temperature for 24 hours, facilitating optimal curing and durability.

Mix epoxy resin and curing agent in the prescribed ratio.

Ensure thorough blending to achieve a homogeneous mixture.

Pour the mixture into the mold box, ensuring the removal of air bubbles via vacuumization.

Allow the epoxy resin to cure at room temperature for 24 hours, ensuring robustness and dimensional stability.

Silver Casting Molds Testing: Ensuring Precision and Performance

Once the graphite jewelry molds are fabricated, rigorous testing ensues to verify their efficacy and precision. Molten silver is poured into the molds, allowing craftsmen to evaluate the resulting jewelry pieces against predetermined standards. Any deviations from the desired specifications prompt meticulous adjustments to the molds, ensuring that each subsequent iteration meets the highest quality standards.

Silver Casting Molds Modification: Fine-Tuning for Perfection

In instances where mold testing reveals discrepancies or imperfections, swift modifications are imperative to maintain manufacturing integrity. Whether through refining the mold design or altering the chosen material, craftsmen leverage their expertise to address any shortcomings promptly. Iterative refinement ensures that the molds achieve optimal performance and fidelity, laying the foundation for consistent excellence in jewelry production.

Silver Casting Molds Mass Production: Scaling Artistry to New Heights

Armed with meticulously crafted molds, artisans embark on the journey of mass production, breathing life into a myriad of silver jewelry designs. Whether through casting, stamping, or other techniques, the manufacturing process unfolds with precision and efficiency. Each mold serves as a conduit for creativity, enabling artisans to replicate intricate designs with unparalleled accuracy and consistency.

With WH graphite manufacturer and products supplier, The manufacturing process of silver jewelry molds epitomizes a harmonious blend of artistry and precision. From the meticulous design phase to the intricacies of mold making and beyond, each step is imbued with craftsmanship and dedication. As these molds pave the way for the creation of exquisite silver jewelry pieces, they stand as a testament to the timeless allure of artisanal craftsmanship in the realm of jewelry design and manufacturing.

English

English