I. Graphite Molds for Continuous and Semi-Continuous Casting of Non-Ferrous Metals

Graphite molds are considered the most suitable material for the production of advanced methods such as direct continuous (or semi-continuous) manufacturing of rods or tubes of non-ferrous metals in a molten state. In production practice, the use of graphite molds has shown that due to its good thermal conductivity (which determines the solidification rate of metals or alloys), excellent self-lubricating properties of the molds, not only increases the casting speed but also produces ingots with precise dimensions, smooth surfaces, and uniform crystal structure. This directly improves the yield, reduces waste loss, and significantly increases product quality. There are two types of continuous casting methods: vertical continuous casting and horizontal continuous casting.

II. Graphite Molds for Centrifugal Casting and Glass Forming

Graphite molds for centrifugal casting have been successfully applied in the United States for the centrifugal casting of bronze sleeves using artificial graphite molds with a wall thickness of over 25 millimeters. To prevent the burning of artificial graphite molds, certain anti-oxidation measures can be taken. If the surface of the mold is burned after casting a certain amount of castings, the size of the hole in the mold can be enlarged for casting large-diameter sleeves.

Graphite molds are indispensable mold materials in glass manufacturing in recent years due to their chemical stability, resistance to molten glass infiltration, and good thermal shock resistance, as well as their small size changes with temperature. They can be used to make glass tubes, bent pipes, funnels, and other various shaped glass bottles.

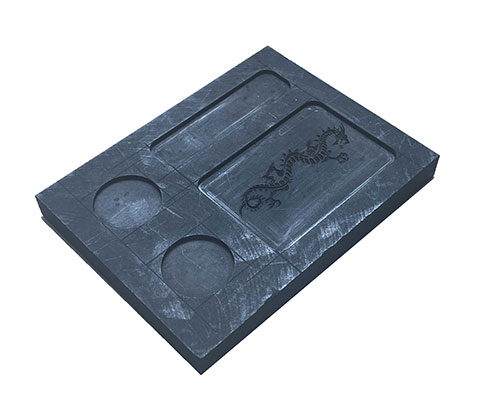

III. Graphite Molds for Pressure Casting and Hot-Pressing Molds

Artificial graphite materials have been successfully used in the pressure casting of non-ferrous metals. For example, molds made of artificial graphite materials have been used to produce castings of zinc alloys and copper alloys for automotive parts, among others.

Artificial graphite hot-pressing molds have the following characteristics in the field of pressure sintering of hard alloys: first, if the pressing temperature is increased to 1350-1450℃, the required unit pressure can be reduced to 67-100 kgf/cm² (which is 1/10 of the cold pressing pressure); second, pressure and heating can be carried out in the same process, and a dense sintered body can be obtained after a short sintering time.

English

English