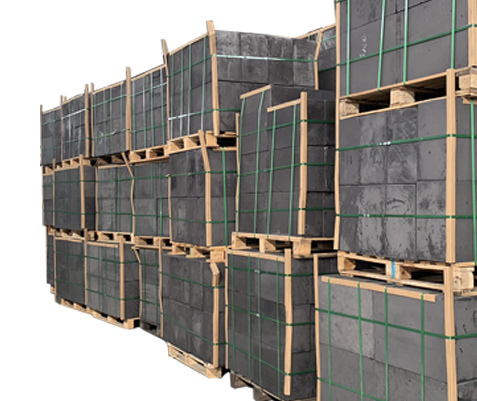

Graphite blocks, silent sentinels of modern industry, stand as testament to the fusion of artistry and engineering. In their genesis lies a saga of metamorphosis, where raw materials undergo a crucible of transformation to emerge as stalwart components coveted across industries. Here, we embark on an odyssey through the labyrinth of graphite block production, unraveling the secrets behind their craftsmanship and extolling their myriad virtues.

The Art of Crafting Graphite Blocks

Carbonization heralds the inception of this transformative journey. Raw materials, sourced from carbon-rich feedstocks such as petroleum coke or coal tar pitch, undergo a fiery baptism at temperatures nearing 1,000°C within an inert atmosphere. Here, impurities are purged, and volatile compounds liberated, leaving behind a residue enriched with carbon—a precursor poised for its next evolution.

Enter the crucible of graphitization, where the carbonized material undergoes a symphony of change under temperatures soaring to approximately 2,800°C, under precise pressure. Within this fiery crucible, carbon atoms engage in a delicate dance, rearranging themselves into the characteristic layered structure synonymous with graphite. Temperature and pressure become maestros, sculpting the material's properties with meticulous precision.

But the journey doesn't conclude with the emergence of graphite; it transcends into the realm of densification. Here, an array of techniques—hot pressing, isostatic pressing, extrusion—vie for supremacy in sculpting the graphite into its final form. Whether sandwiched between heated plates or subjected to uniform pressure from all directions, each method leaves its indelible mark on the graphite, imbuing it with the requisite strength and density.

The Virtues of Graphite Blocks

Why choose graphite blocks over other materials? The answer lies in their unparalleled virtues, each a testament to their versatility and indispensability across industries.

1. High Thermal Conductivity:

Graphite reigns supreme as one of the world's best thermal conductors, dissipating heat with unparalleled efficiency. This makes graphite blocks indispensable in heat sinks, crucibles, and other high-temperature applications, where rapid and even heat dissipation is paramount.

2. Electrical Conductivity:

In the realm of electrical conductivity, graphite stands tall, efficiently conducting electricity with ease. It finds its calling in electrodes and electrical components, where the seamless flow of current is essential for optimal performance.

3. Wear Resistance:

Graphite's resistance to wear and abrasion renders it a stalwart in applications subjected to rubbing or friction. Bearings, seals, and components grappling with high loads find solace in the wear-resistant embrace of graphite blocks.

4. Chemical Inertness:

Unfazed by chemical onslaughts, graphite stands as a bastion of chemical inertness, impervious to most corrosive agents. This makes it an ideal candidate for applications where corrosion poses a threat, safeguarding components against chemical degradation.

5. Low Friction Coefficient:

With a whisper of friction, graphite glides effortlessly, its low friction coefficient making it an ideal lubricant and wear-resistant material. Bearings, seals, and components traversing the realm of friction find refuge in the smooth embrace of graphite blocks.

6. High Strength to Weight Ratio:

Graphite's high strength-to-weight ratio bestows upon it the dual virtues of strength and lightweight, making it a preferred choice in weight-conscious applications. From aerospace components to automotive marvels, graphite blocks find their niche in realms where weight is a paramount concern.

7. Radiation Shielding:

In the shadowy realms of radiation, graphite emerges as a beacon of protection, its shielding capabilities rendering it indispensable in nuclear power plants and high-radiation environments.

8. Biocompatibility:

Gentle on the human touch, graphite's biocompatibility ensures its acceptance in the realm of medical implants and devices, where interaction with the human body demands materials of utmost safety and compatibility.

With graphite manufacturer and products supplier, In the grand tapestry of modern industry, graphite blocks stand not merely as components but as pillars of innovation and resilience. From their fiery genesis to their versatile applications, each graphite block embodies a saga of craftsmanship and mastery, woven with threads of science and artistry. In their silent vigil across industries—from aerospace to automotive, from chemical to medical—they stand as beacons of human ingenuity, steadfast and unwavering amidst the tumult of progress.

English

English