With its excellent electrical conductivity, high temperature resistance, lubrication and other properties, graphite powder quickly seizes the share of various industries with great advantages. It is soft, dark gray, and has a greasy feel that can stain paper. So what is the role of graphite powder?

Ⅰ. About graphite powder

Graphite powder is a kind of mineral powder, the main component is carbon, it is soft, black and gray; it has a greasy feeling and can pollute the paper. The hardness is 1 to 2, and the hardness can be increased to 3 to 5 with the increase of impurities in the vertical direction. Specific gravity is 1.9 to 2.3. Under the condition of isolating oxygen, its melting point is above 3000 ℃, which is one of the most temperature-resistant minerals.

Ⅱ. What are the functions of graphite powder?

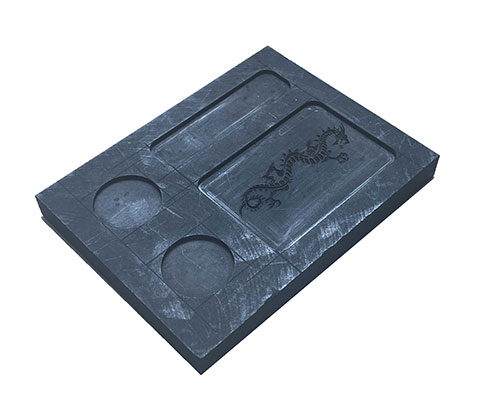

1. Metallurgy and alloy: This is mainly metal alloy raw material and powder metallurgy release agent. The quality of special graphite powders used in these industries is closely related to their purity: the higher the purity, the better the lubrication effect. It has the following advantages: high temperature resistance, increased original strength, easy mixing, uniform particles.

2. Filler or improver: In order to better improve the conductivity, compression resistance and wear resistance of materials, graphite powder is used as filler or performance improver for various composite materials and rubber and plastics.

3. Base material: This is mainly corrosion-resistant lubricant base material and high temperature-resistant lubricant base material.

4. Fertilizer industry: As a mold release lubricant, it is mainly used in the production of catalysts in the fertilizer industry.

5. Conduction: use them to prepare conductive liquid and make carbon film resistors and conductive dry molds.

Different specifications of graphite powder have different uses; the larger the mesh number, the smaller the particle size and the better the quality; the higher the carbon content, the better the electrical conductivity and high temperature resistance, and the wider the use.

Ⅲ. The difference between graphite powder and iron powder

Graphite powder belongs to the hexagonal crystal system and has a layered structure, which is widely used in industry. Graphite powder and iron powder are very similar in appearance, and it is sometimes difficult for us to identify them. So what are the methods of distinguishing graphite powder and iron powder?

Chemistry:

1. Mixing and heating: Add copper oxide to graphite powder and iron powder respectively for mixing and heating. Adding graphite powder will produce clear lime water and become turbid CO2, but iron powder will not have this situation.

2. When dilute sulfuric acid or dilute hydrochloric acid is added to the iron powder, bubbles will appear.

Physics:

1. Heating: Graphite powder is ignited in the air, but iron powder will turn black.

2. Magnet: Iron powder can be attracted by magnets, but graphite powder cannot be attracted by magnets.

3. Touch: Graphite powder has a greasy feeling, but iron powder does not.

English

English