What are isostatic graphite blocks?

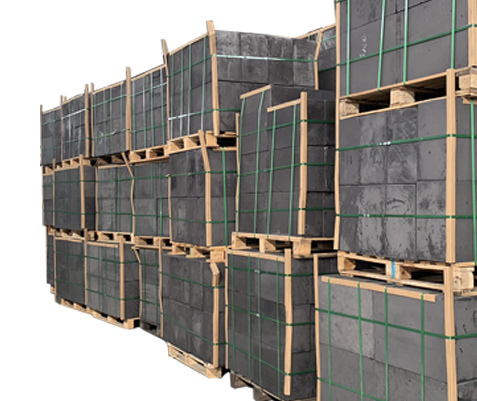

Graphite is not only useful in daily life, but also plays an important role in cutting-edge defense technology. It is a new type of material that is attracting attention. Isostatic graphite blocks are made by pressing high-purity graphite. Isostatic graphite is a new product that has been developed internationally in the past 50 years and is closely related to today's high-tech industry. Isostatic graphite block is mainly used in large copper production lines. Since 1985, China has imported more than 30 production lines from Austria, France, Switzerland, Japan and other countries. More than 100 domestically designed and manufactured production lines using graphite molds have been established in China. Isostatic graphite is a new type of graphite material and a fine product in the graphite material family. Due to its excellent properties, it is bound to be closely related to high-tech and cutting-edge defense technology, becoming one of the most valuable new materials of the 21st century. With economic development, the international market potential for isostatic graphite is increasing day by day, and its development prospects are enormous. WH graphite block supplier will be your trustworthy partner.

What are the characteristics of isostatic graphite blocks?

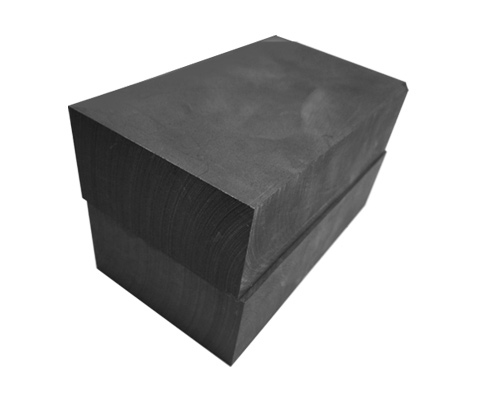

Isostatic graphite blocks are named for their production process. They are made using isostatic forming. During the forming process, the material is subjected to uniform pressure from liquid, which gives the molded graphite block isotropic properties. In other words, the properties of the material are not dependent on the size, shape, or direction of the sample taken from the block. Isostatic graphite blocks are generally called isotropic graphite. The isotropy of isostatic graphite blocks is between 1.0 and 1.1.

This characteristic is influenced by factors such as heat treatment, isotropy of powder particles, and forming process. The isotropy of the surface of heat-treated isostatic graphite blocks is better than that of the inside. If the binder and the powder are not mixed evenly, it will also affect the isotropy of the isostatic graphite blocks.

The second characteristic of isostatic graphite blocks is that they have large size with fine structures. The uniform pressure during the isostatic forming process overcomes the uneven density caused by die pressing, greatly reducing the chance of cracking during the production of large, fine-structured products.

It is precisely because of this feature that isostatic graphite blocks also have homogeneity characteristics. The internal structure is relatively uniform, and the volume density, resistivity, and strength performance of each part do not differ significantly, making it a homogeneous graphite material. Compared with ordinary graphite materials, the advantages of isostatic graphite blocks are particularly prominent, and they have broad application prospects in fields such as semiconductors, atomic energy, aviation, and continuous casting.

English

English