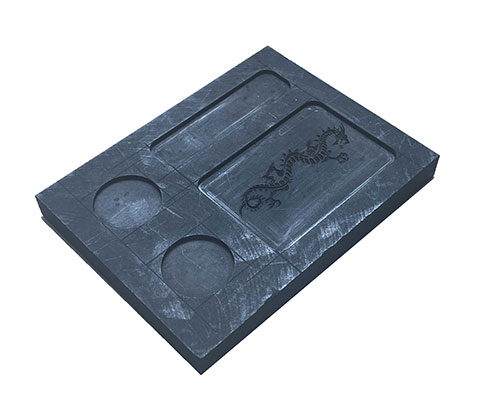

Any product made from graphite as a raw material can be called a graphite product. The raw materials used to produce graphite products can be divided into two types: artificial graphite and natural graphite. That is to say, various finished products made from artificial graphite and natural graphite through processing, such as carbon rods, graphite rods, graphite blocks, graphite paper, etc. used in dry batteries, as well as industrial graphite rotors, graphite bearings, etc. are all graphite products. Graphite products made according to the characteristics of graphite include graphite rods, graphite blocks, graphite plates, graphite molds, graphite rings, etc. Graphite products have good adsorption properties. The hollow structure of charcoal makes it have good adsorption properties, so charcoal is often used as an adsorbent material for absorbing water, odor, etc.

Due to the many excellent properties of graphite, it has been widely used in metallurgy, machinery, electrical, chemical, textile, national defense, and other industrial sectors. Therefore, graphite products have been widely used in metallurgy, chemical industry, petrochemical industry, high-energy physics, aerospace, electronics, and other fields.

Identifying the Quality of Graphite Products:

To identify the quality of a product, start with the raw materials and look at the material's Shore hardness. If the hardness of the graphite product is greater than 80, it will cause wear to the cutting tools and may affect the consistency of the aperture. In addition, if the Shore hardness is greater than 80, it can also easily cause safety hazards such as edge collapse.

Resistance. Different graphite materials have different resistances. If the average particle size is the same, the higher the resistance, the slower the discharge speed, and the higher the hardness and strength.

The degree of bending strength of the material. The bending strength of the material is a direct reflection of its strength. When the bending strength of the material is large, making extremely fine and deep rod-shaped electrodes can also avoid breakage. For high-precision electrodes, materials with good strength should be selected as much as possible.

The average particle size of the graphite material used in the conductive material of lithium batteries is generally below 5 microns. Because this can improve the bending strength of graphite and is also suitable for fine surface processing, with less loss. The smaller the average particle size of the material, the more uniform the discharge. If the average particle size is large, the workmanship will be relatively rough.

Many people may think that high-quality graphite products have too high production costs. In fact, the opposite is true. The loss of high-quality graphite products is actually very small. High-quality graphite can truly reduce production costs and extend the service life of products.

English

English