Electrical Discharge Machining (EDM) is a precise and versatile machining method widely used in various industries. In EDM, the choice of material for the electrodes is crucial for achieving accurate and intricate machining. Among the materials available, EDM graphite (Electrical Discharge Machining Graphite) has gained prominence due to its unique properties that make it an ideal choice for traditional downward sinking EDM applications. In this comprehensive guide, we will delve into the properties of EDM graphite, its diverse applications, and the variety of suppliers available, providing insights into why it is the preferred material for EDM.

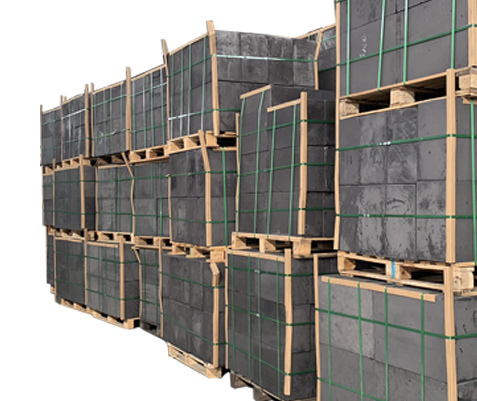

Properties of EDM Graphite Blocks

EDM graphite blocks is prized for its distinct properties that set it apart as an excellent material for EDM. These properties make it a preferred choice for manufacturing precision parts and components. Let's explore these unique attributes:

1. Fine Detail

EDM requires materials that can be precisely machined to create intricate and detailed parts. EDM graphite blocks, with its fine-grain structure, is well-suited for achieving these intricate details. The fine grain allows for precise machining, ensuring the creation of highly accurate and complex shapes. This makes EDM graphite blocks an ideal material for industries where precision and attention to detail are paramount.

2. Low Wear

In EDM applications, the wear and tear on the electrode material can significantly affect the quality and consistency of the machining. EDM graphite exhibits low wear characteristics, which means it can withstand the repetitive sparking and erosion that occurs during the machining process. This low wear rate contributes to the extended lifespan of the EDM graphite electrodes, reducing the frequency of electrode replacement and enhancing cost-efficiency.

EDM Graphite Blocks Applications

The exceptional properties of EDM graphite blocks make it a preferred material for a wide range of EDM applications. Let's explore the common uses of EDM graphite in precision machining:

1. EDM Electrodes

EDM electrodes are a fundamental component of the EDM process. They are used to shape, cut, and refine various materials with exceptional precision. EDM graphite blocks, with its fine detail and low wear properties, is often employed as the material of choice for manufacturing EDM electrodes. Its ability to maintain precise shape and withstand the erosive nature of the EDM process ensures the production of high-quality and finely detailed parts.

2. Precision Machining

The ability to achieve fine detail and maintain dimensional accuracy makes EDM graphite blocks suitable for precision machining applications. Industries that demand intricate and complex parts, such as aerospace, medical, and tooling, rely on EDM graphite blocks to meet their precise machining needs. Whether it's creating intricate medical implants or aerospace components, EDM graphite blocks plays a crucial role in producing high-quality, precision parts.

3. Heat Shock Resistance

EDM machining generates heat during the process. Heat shock resistance is a vital property in EDM electrode materials. EDM graphiteblock is known for its excellent resistance to thermal shock, which ensures that it can withstand the extreme temperature fluctuations experienced during EDM operations. This property contributes to the durability and reliability of EDM graphite in precision machining applications.

Choosing the Right EDM Graphite Supplier

When considering EDM graphite blocks for your precision machining needs, it's essential to choose a reputable supplier. Here are some factors to consider when selecting an EDM graphite blocks supplier:

1. Variety of Types and Sizes

A reliable supplier should offer a wide range of EDM graphite types and sizes to cater to diverse applications. Whether you need different grades, shapes, or dimensions of EDM graphite blocks, a supplier with a comprehensive product range ensures you can find the material that best suits your specific needs.

2. Quality and Consistency

Consistency in material quality is paramount for precision machining. A reputable EDM graphite blocks supplier should provide high-quality, consistent materials to ensure precision and accuracy in your machining processes. Quality assurance and adherence to industry standards are indicators of a trustworthy supplier.

3. Technical Support and Expertise

Precision machining often involves complex projects and unique requirements. Choosing a supplier with technical expertise and excellent customer support can be invaluable. A knowledgeable supplier can provide guidance, recommendations, and solutions to ensure successful machining projects.

4. Reliability and Delivery

Timely delivery is crucial to keep your machining projects on schedule. A dependable EDM graphite blocks supplier should have a track record of reliable and prompt deliveries. This ensures that you receive your materials when you need them, avoiding production delays.

In the world of precision machining, EDM graphite blocks stands out as an exceptional material for EDM applications. Its unique properties, including fine detail, low wear, and heat shock resistance, make it the material of choice for producing intricate and accurate parts. Industries such as aerospace, medical, and tooling rely on EDM graphite blocks to meet their precision machining needs.

Selecting the right EDM graphite supplier is crucial for ensuring the success of your precision machining projects. A reputable supplier offers a variety of types and sizes, maintains high material quality and consistency, WH EDM graphite electrodes manufacturer and supplier provides technical support, and ensures reliable and timely delivery. With the right supplier and the advantages of EDM graphite blocks, you can achieve precision and accuracy in your machining endeavors, creating high-quality, finely detailed components for a wide range of applications.

English

English