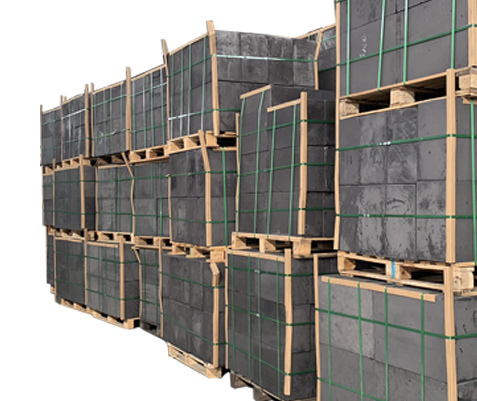

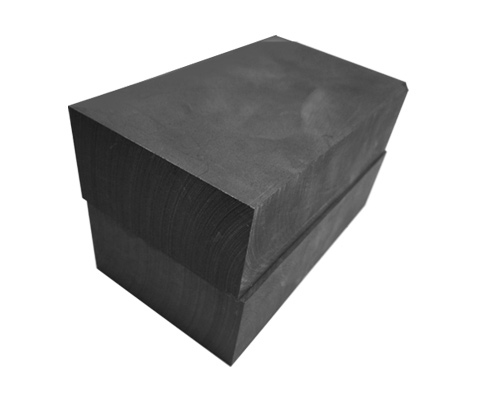

Isostatically pressed graphite blocks are made of isostatically pressed graphite material and has different sizes and different qualities. Isostatically pressed graphite has its own properties and therefore has special applications. Due to the special properties of isostatic graphite blocks, they are widely used in metallurgy, machinery, petroleum, chemical industry, nuclear industry, national defense and other fields. What are the main applications? Let WH graphite block supplier explain for you.

Ⅰ. Application of isostatic graphite block

1. Refractory materials: In the smelting industry, graphite is used for graphite crucibles for protecting steel ingots, and for smelting furnaces lined with magnesia-carbon bricks.

2. Conductive materials: In the electrical industry, isostatic graphite block is widely used as coatings for electrodes, brushes, rods, carbon tubes, and TV picture tubes.

3. Wear-resistant materials and lubricants: In much mechanical equipments, graphite is used as wear-resistant and lubricating materials, which can slide at a speed of 100m/s in the temperature range of -200 to 2000℃, with or without lubricants.

4. Sealing materials: Flexible graphite, piston ring gaskets, and seals for centrifugal pumps, steam turbines, steam turbines, and corrosive medium conveying equipment.

5. Corrosion-resistant materials: Graphite containers, pipes, and equipment can withstand the corrosion of various corrosive gases and liquids and are widely used in petroleum, chemical, hydrometallurgy, and other departments.

6. Insulation, high-temperature resistance, radiation protection: Isostatic graphite blocks can be used as neutron moderators in nuclear reactors, rocket nozzles, missile nose cones, aerospace equipment parts, and insulating materials, and radiation-resistant materials.

Ⅱ. The characteristics of isostatic graphite block

1. High-temperature resistance: the melting point of the carbon graphite rod is 3850±50℃, and the boiling point is 4250℃. Even if it burns under the ultra-high temperature arc, the weight loss is small and the thermal expansion coefficient is small. The strength of the graphite rod increases with the increase in temperature, and at 2000 °C, the strength of the graphite doubles.

2. Electrical and thermal conductivity: The electrical conductivity of isostatic graphite blocks is one hundred times higher than that of non-metallic minerals. Thermal conductivity is better than steel, iron, lead, and other metal materials. Its thermal conductivity decreases with the increase in temperature, and even at very high temperatures, the molded graphite block still remains insulating.

3. Lubricity: Graphite lubrication depends on the size of the graphite flakes. The larger the flakes, the smaller the friction coefficient and the better the lubrication performance.

4. Chemical stability: Graphite has good chemical stability at room temperature and is resistant to corrosion by acids, alkalis, and organic solvents.

5. Plasticity: Graphite has good toughness and can be crushed into flakes.

6. Thermal shock resistance: The isostatic graphite block used at a high temperature can withstand severe changes in temperature without damage. If the temperature changes suddenly, the volume of graphite will change very little, and cracks will not occur.

English

English