1. About molded graphite

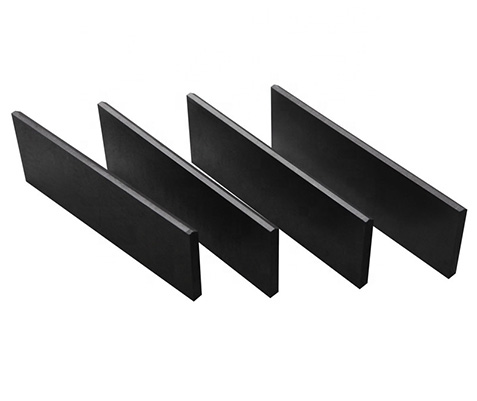

Molded graphite refers to graphite with a carbon content > 99.99%. It has good electrical conductivity, high-temperature resistance, oxidation resistance, low resistivity, corrosion resistance, high purity, self-lubrication, thermal shock resistance, isotropy, easy precision machining, and other excellent features. Molded graphite flakes have complete crystallization with thin flakes and good toughness, and also have excellent physical and chemical properties. They are ideal inorganic non-metallic materials and are widely used in aerospace, solar photovoltaic and semiconductors, continuous casting, cemented carbide, and electronic mold sintering industries.

Molded graphite has unique advantages in the production of electric heating elements, structural casting molds, crucibles and vessels for smelting high-purity metals, heaters for single crystal furnaces, EDM graphite, sintering molds, electron tube anodes, metal coating, graphite crucibles for semiconductor technology, graphite anodes and grids for electron emission tubes, thyratrons and mercury arc rectifiers. In particular, large-scale and high-quality molded graphite, as an alternative material, has a broad application space in the field of high-tech and new technologies, and has a wide range of application prospects.

2. The purification method of molded graphite

The purification methods of molded graphite are mainly divided into two categories: one is wet purification, including flotation method, acid-base method, hydrogen acid method; the other is fire purification, including chlorination roasting method and the high-temperature method. The difference in the production process of molded graphite can be divided into one-immersion one-baked graphite, two-immersion three-baked graphite, three-immersion four-baked graphite, and four-immersion five-baked graphite, etc. The density of two-immersion three-baked graphite is above 1.7, and the density of three-immersion four-baked graphite is above 1.8. High thermal conductivity nanoflake carbon powder is a synthetic molded graphite with higher purity, smaller particle size, and thickness within the nanoscale range, but its radial width can reach several to tens of micrometers, with a super large shape ratio. It maintains the original planar carbon six-membered ring conjugated crystal structure of graphite and has excellent mechanical strength, electrical conductivity, and thermal conductivity, as well as good lubrication, high temperature, and corrosion resistance.

3. Application of molded graphite

Molded graphite is widely used in refractory materials and coatings in the metallurgical industry, stabilizers for pyrotechnic materials in the military industry, pencil leads in the light industry, carbon brushes in the electrical industry, electrodes in the battery industry, catalyst additives in the fertilizer industry, etc. After deep processing, molded graphite can produce high-tech products such as graphite emulsion, graphite sealing materials and composite materials, graphite products, and graphite anti-friction additives, which have become important non-metallic mineral raw materials in various industrial sectors.

English

English