Graphite is a transitional crystal between atomic crystals, metal crystals and molecular crystals. In the crystal, covalent bonds are formed between sp2-hybridized carbon atoms in the same layer, with each carbon atom connected to three other carbon atoms. Six carbon atoms form a regular hexagonal ring in the same plane, which is stretched to form a layered structure. Graphite can be used as an abrasive, lubricant, high purity graphite is used as a neutron moderator in atomic reactors, and it can also be used to manufacture crucibles, electrodes, brushes, dry batteries, graphite fibers, heat exchangers, cooling devices, arc furnaces, arc lamps, and pencil cores. Let WH EDM graphite electrodes manufacturer and supplier explore for you.

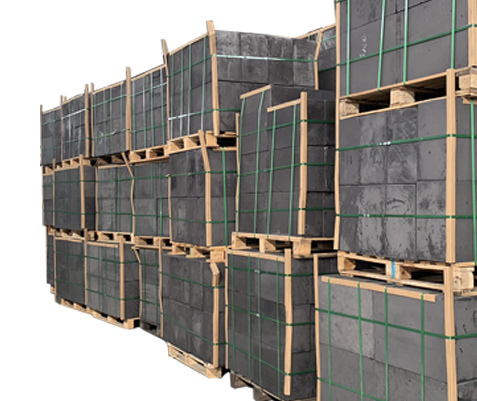

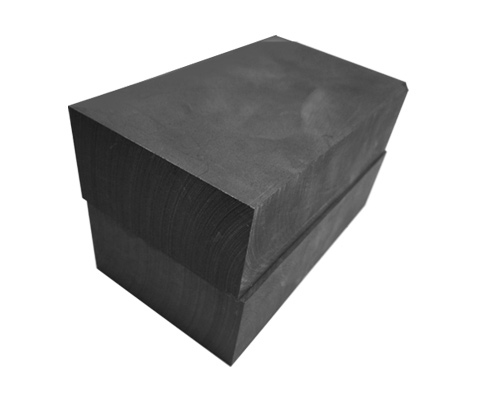

1. Isostatic graphite block used in electrical discharge machining

Electrical discharge machining has advantages that traditional cutting processing does not have, and can work on hard materials, high temperature resistant alloys, and other difficult-to-process materials. Currently, about 70% of the electrode materials used in Chinese electrical discharge machining are purple copper, and around 30% are graphite electrodes. Using isostatic graphite as a graphite electrode has some advantages that copper electrodes do not have: it does not melt under high temperature conditions and can maintain a certain strength; the electrode consumption is small during electrical discharge machining; the processing speed is fast; the material has good thermal stability during cutting and is not easily deformed; the quality is light, which can ensure the surface quality and size accuracy of the workpiece and make the surface easy to process.

With the development of science and technology and the needs of practical production and processing, electrical discharge machining is gradually developing towards precision, refinement, high speed, high efficiency, green and composite processing. However, in these processes, the electrical discharge machining tool electrode will suffer serious damage, which will affect the surface quality and size accuracy of the product. Therefore, how to reduce the wear and tear of the tool electrode and achieve high-speed, low-cost, precision machining is the goal that electrical discharge machining is constantly pursuing. EDM graphite blocks need to be developed in the direction of smaller particle size and larger dimension.

2. Isostatic graphite blocks used in nuclear industry

The working conditions of nuclear reactors are extremely harsh, requiring materials to have the characteristics of high density, high strength, high temperature resistance, corrosion resistance, low thermal expansion coefficient, and thermal stability. Therefore, isostatic graphite block is applied in nuclear reactors. Isostatic graphite has the function of slowing down and reflecting neutrons in atomic energy reactors, as well as serving as structural materials, such as support columns, thermal conduits, fuel elements, and other thermal structural components, as well as producing graphite balls, core materials, motors, and other nuclear graphite products.

English

English