Our graphite blocks for sale have good absorption. The void structure of carbon makes carbon has good adsorption, so carbon is often used as adsorption material, used to absorb water, odor, toxic substances, and so on.

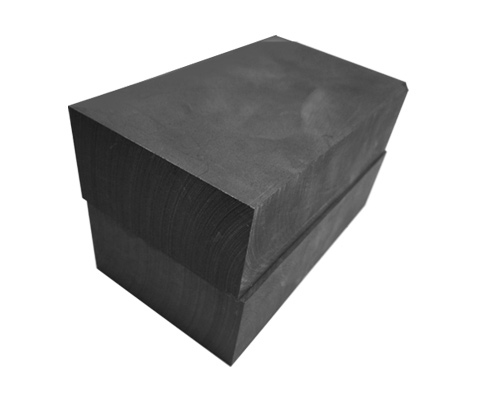

Graphite is an allotroph of carbon, gray black graphite carbon block, opaque solid graphite block, melting point of 3652℃, boiling point of 4827℃. Solid carbon graphite block, a stable chemical property, is corrosion resistance, and is hard to react with acid, alkali and other agents. Carbon graphite block burns in oxygen at 687℃ to form carbon dioxide. Carbon graphite blocks can be oxidized by strong oxidants such as concentrated nitric acid and potassium permanganate. The graphite carbon block also can be used as an antiwear agent or lubricant. High purity graphite as a neutron decelerating agent in the atomic reactor, can be used to manufacture graphite crucible, electrode, brush, dry cell, graphite fiber, heat exchanger, cooler, arc furnace, arc lamp, pencil core, and so on.

Carbon graphite blocks is used in silicon carbide furnaces and other metallurgical furnaces, resistance furnace lining, and conductive material, graphite vacuum furnace as well as permeable graphite heat exchanger.

OEM graphite blocks is widely used in semiconductor, metallurgy, continuous casting, photovoltaic, EDM with EDM graphite blocks, chemical, steel, glass and ceramics, and other fields. The quality of China carbon graphite blocks is good with stable performance.

Our graphite blocks for sale have good absorption. The void structure of carbon makes carbon has good adsorption, so carbon is often used as adsorption material, used to absorb water, odor, toxic substances, and so on.

Carbon graphite block has good thermal conductivity, fast heat transfer, uniform heating and fuel saving. The baking dish and pot made of graphite are heated quickly, and the baked food is heated evenly and cooked from the inside out. The heating time is short, which not only tastes pure but also locks the original nutrients of the food.

China graphite blocks have good chemical stability at room temperature and are not eroded by any strong acid, strong alkali, and organic solvents. Therefore, even if the long-term use of graphite products loss is very small, as long as clean as new.

Graphite carbon block material has strong oxidation and reduction effect. In particular, graphite mattress can produce negative oxygen ions after heating, so that the activity of the surrounding articles, maintain human health, effectively prevent aging, make the skin full of luster and elasticity.

Carbon in 2000-3300℃ high temperature environment after at least a dozen days and nights of graphitization process to become graphite, therefore, graphite products environmental health, no radioactive pollution, high temperature resistance.

Carbon graphite block has good lubricity and is often used as a lubricant in mechanical production, in order to replace the lubricating oil that cannot be used under high temperature and high pressure.

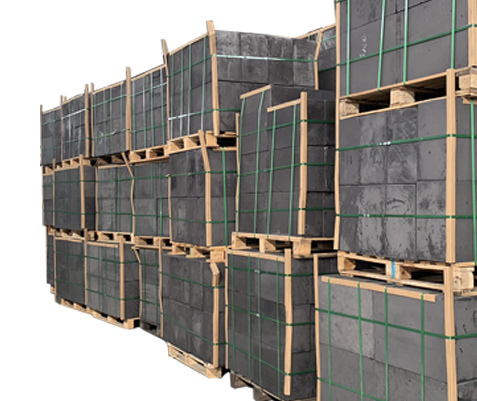

WH Graphite graphite block supplier understand the importance of quality when it comes to graphite blocks. That's why we source our materials from trusted suppliers and employ stringent quality control measures throughout the manufacturing process. Our graphite blocks for sale are known for the exceptional strength, durability, and thermal conductivity.

Whether you need molded graphite block, electrodes, crucibles, or any other purpose, WH Graphite, the professional graphite blocks supplier, has the right solution for you. Our products come in various sizes, grades, and configurations to suit your specific needs.

Our team of experienced professionals will work closely with you to understand your needs and deliver a customized solution that meets your expectations.

WH Graphite graphite blocks supplier believe that top-quality carbon graphite blocks should be accessible to all businesses. Therefore, we offer competitive graphite blocks price without compromising on the quality of our products. We strive to provide the best value for your investment, making us a trusted choice among customers looking for cost-effective solutions.

If you want to buy large graphite blocks, WH Graphite graphite blocks supplier is your best chioce.

Our OEM carbon graphite block mainly uses high-quality petroleum coke as raw material, coal asphalt, or synthetic resin as the binder.

Through the preparation of raw materials, ingredients, mixing kneading, pressing, crushing, remixing kneading, molding, many times of roasting, many times of dipping, purification and graphitization, machining, and made of graphite block.

WH graphite block supplier headquarter is located in Henan, China. Since 2018, our products have been sold to domestic market (60.00%), North America (10.00%), East Asia (9.00%), Africa (8.00%), South Asia (7.00%), Middle East (3.00%) and Western Europe (3.00%).

Each process is produced in strict accordance with the quality standard manual.

Pre-production samples must be available before mass production.

Final inspection is always made before the final shipment of your graphite welding blocks.

High Purity Graphite Block, isostatic graphite block, EDM Graphite, graphite block with high density, Molded Graphite, Extruded Graphite, Graphite Round, Natural Flake Graphite Powder, Graphite Rod, Graphite Plate, Graphite Crucible, also can be customized according to customer drawings of various graphite moulds.

Pingdingshan Wanhui graphite Co., Ltd. is a professional graphite block supplier, with advanced technology and production equipment, through the ISO9001 quality certification, has an independent R & D team and production lines, can provide professional graphite solutions.

Acceptance of delivery terms: negotiate with customer.

Currency of payment accepted: USD&EUR.

Payment accepted: T/T.